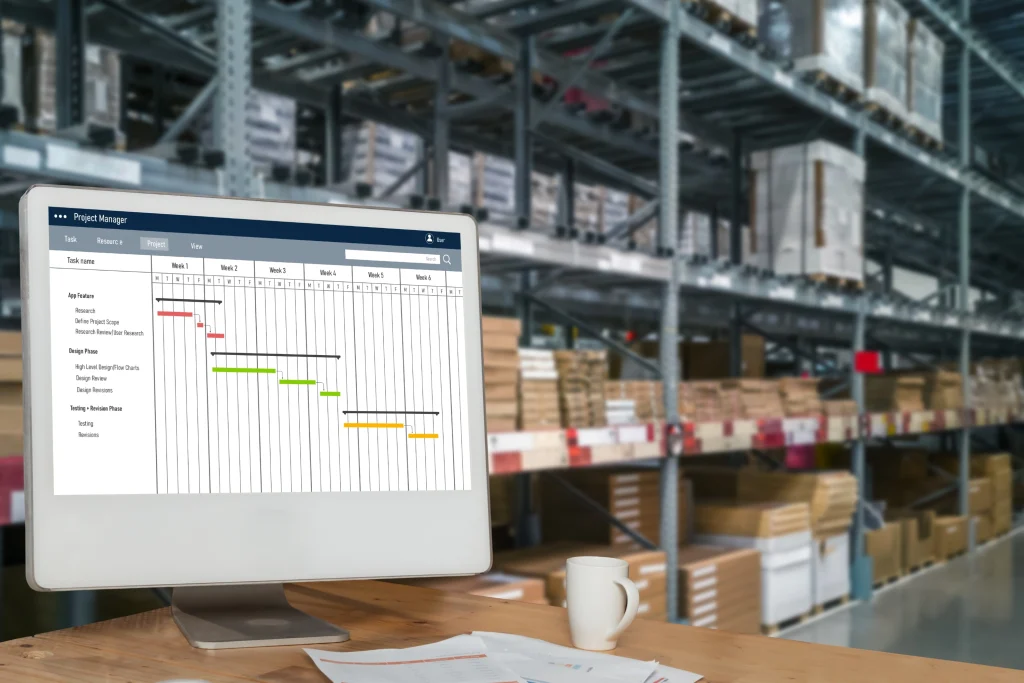

In order to engage in capacity planning and production scheduling, you need to control how much raw material, parts, and subassemblies you process at a given time. There are several types of inventory stock that organizations have: raw materials, finished products and work-in- process and service supplies and replacement parts, buffer stock, anticipation stock, and transit inventory. If you cannot control the location of your product or raw materials from both a physical and a recordkeeping standpoint, then your inventory accuracy will suffer. It’s important to have overall understanding of Inventory dynamics to succeed as an organization. This eBook looks at the purpose inventory, types of stock, importance of physical locations to control inventory, placement theories, inventory stratification, groupings, bar code scanning, replenishment methods, inventory minds, etc.